Process standards

No process improvement without standards

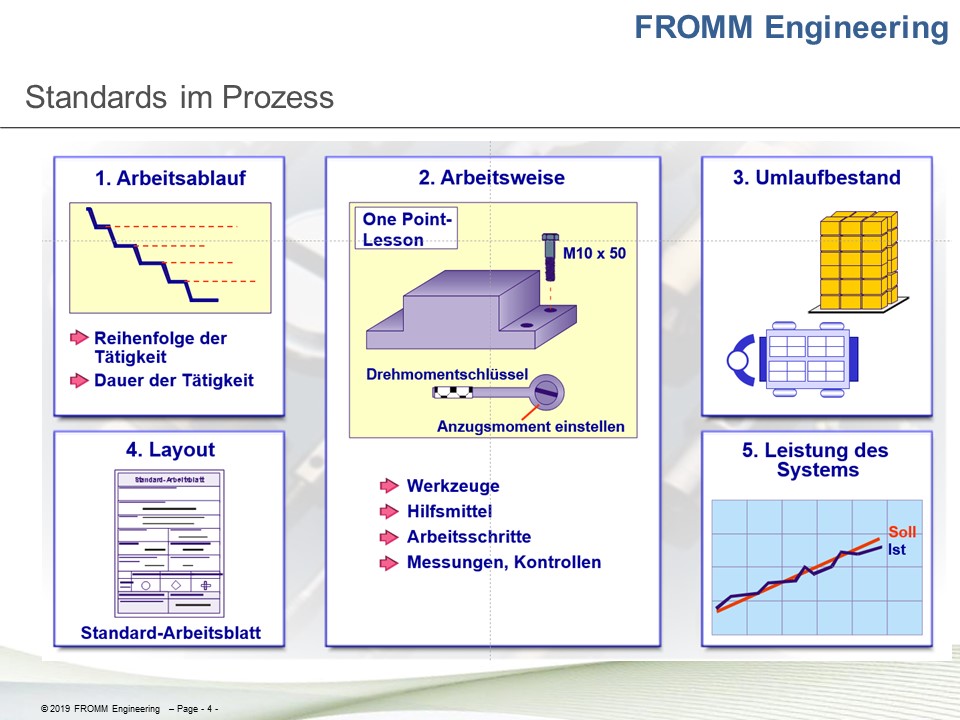

In a well-organized factory, there is a clear regulation of which material, in what quantity, on what area and how and with what is worked at the various workplaces. These game rules are documented and only one suggestion for improvement leads to a change of the game rules. Because only those who know where they stand can determine whether they are improving.

Visualize standards

Standards have to be visualized for everyone in the factory. However, the publication of standards only makes sense if you can see at a glance whether they are being complied with. Both the employees and the responsible managers must be able to immediately recognize whether the process standard is being followed or not.

Audit standards

Executives from all hierarchical levels participate in the audit. For this, a detailed audit plan must be drawn up, from which it can be seen who carries out which audit and when. The employees do not perceive the auditing process as a control, since they use their standard worksheets to define the height of the bar themselves. That is why management's interest in compliance with process standards is perceived as positive: those up there do not care what we do here.