One Piece Flow

One-piece flow is a production that is logistically based on a production line or even an assembly line, but in whose work organization semi-autonomous group work or at least job rotation is used. In contrast to a conventional assembly line, the employees do not stay in place while one part after the other is being brought in for processing, but they accompany the workpiece along the entire path, which leads from one work system to the next without interruption until it is completed.

The concept of the one-piece flow makes it easier to change the product variant from piece to piece and to dispense with batch production. Since the employees know from the start which variant they are currently building, they can concentrate on it and do not need to re-inform themselves about each work system. Monotonous mix-ups are significantly reduced. For the employees, the larger, perhaps complete, work content increases motivation to work (see work structuring). The quality can be tracked better, delivery times are shortened.

In its pure form, one-piece flow means that all employees in a production process master all the work involved in this work, also perform it and are therefore responsible for the overall process and the resulting product.

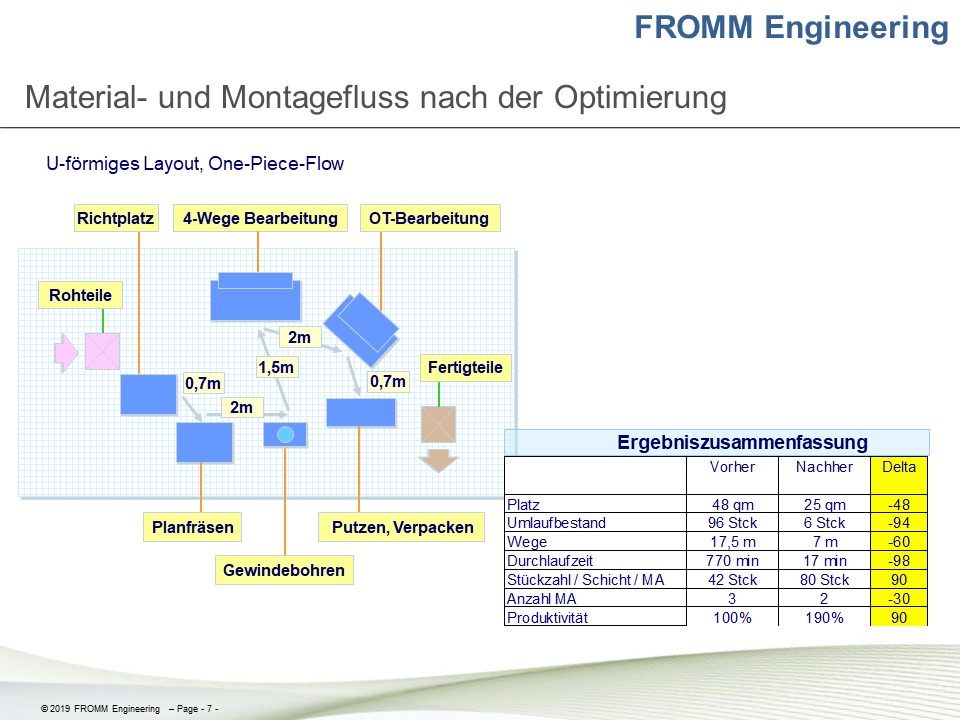

U-cell assembly

In practice, the workplaces of the production process are arranged in so-called (production) islands; the accompaniment of the product is thus reduced to the drainage sections in the island. This is to prevent the scope of tasks from becoming too large for the individual employees and losing them in routine and practice and thus in the speed and quality of work. On the other hand, the individual employees no longer work on the entire product.

The employee starts at the first work system on the island and runs through the entire area by moving the product from work system to work system until the last associated work system is reached. There the product is usually checked and passed on to other responsibilities.

The employee goes back to the first work system and starts his process again. The start and end point of such an island should therefore be as close together as possible. For this reason, U-shaped or even Omega lines are used. Such lines, also called chaku-chaku, are increasingly being used, as far as the workshops allow. Great advantages of this method compared to conventional flow production are:

- High flexibility regarding variants,

- high (personnel) flexibility in the case of fluctuations in production quantities, since not all workplaces need to be filled,

- reduced delivery times, since there is no need to wait until a lot has come together for a variant,

- reduced stocks and thus reduced space and capital requirements due to lot size 1,

- better controlled quality as well

- better conditions for mass customizing and versatile production systems.

However, higher qualification requirements are imposed on employees and their pay is likely to increase.